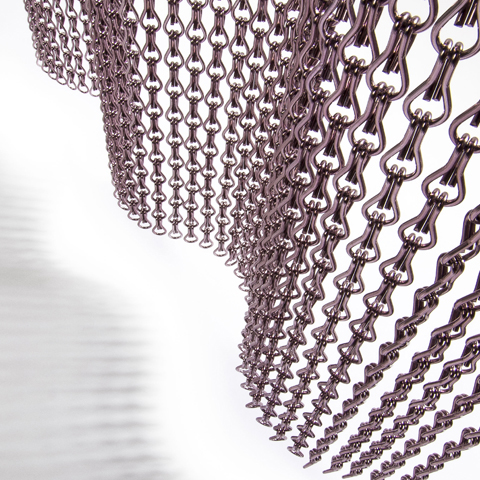

100% Original Ss Wire Mesh Belt - Wire Mesh Conveyor Belt Flat-Flex Type – JIKE Detail:

Whatever your needs, Wire Belt Company’s Technical Sales Engineers will work with you to determine the best Flat-Flex®belt configuration to accommodate your product, process, application and maintenance requirements.

If you require a unique belt or conveyor to deliver the best conveyor performance, we will not hesitate to design and deliver a totally customised solution for your application. Our aim is your complete satisfaction with the performance of our products. We are confident we can provide the right belt, sprockets and other components you need.

Standard Belt Data

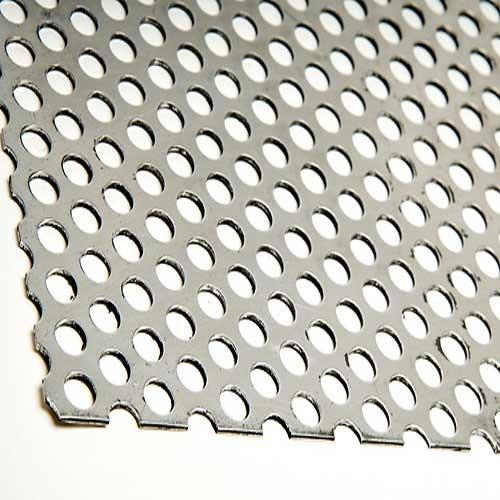

Flat-Flex® is available in a wide range of wire diameters & pitches. The following table gives a broad indication of availability:

|

Wire Dia. Range |

Pitch Range |

|

0.9mm – 1.27mm |

4.0mm – 12.7mm |

|

1.4mm – 1.6mm |

5.5mm – 15.0mm |

|

1.8mm – 2.8mm |

8.0mm – 20.32mm |

|

3.4mm – 4.0mm |

19.05mm – 25.0mm |

Note: Due to pitch to wire dia. combination ratios not all pitches are available in the corresponding wire diameters stated.

The below data is an extract from our full range of Flat-Flex® belting.

|

Pitch and Wire Diameter (mm) |

Average weight (kg/m²) |

Max belt tension per space (N) |

Minimum transfer roller outside diameter (mm) |

Minimum recommended reverse bend diameter (mm)* |

Typical open area (%) |

Edge Availability |

||

|

Single Loop Edge (SLE) |

Double Loop Edge (DLE) |

C-Cure Edge (SLE CC) |

||||||

|

4.24 x 0.90 |

1.3 |

13.4 |

12 |

43 |

77 |

• |

• |

|

|

4.30 x 1.27 |

2.6 |

44.5 |

12 |

43 |

67 |

• |

||

|

5.5 x 1.0 |

1.35 |

19.6 |

12 |

55 |

79 |

• |

• |

|

|

5.5 x 1.27 |

2.2 |

44.5 |

12 |

55 |

73 |

• |

• |

|

|

5.6 x 1.0 |

1.33 |

19.6 |

12 |

56 |

79.5 |

• |

• |

|

|

5.64 x 0.90 |

1.0 |

13.4 |

12 |

57 |

82 |

• |

• |

|

|

6.0 x 1.27 |

1.9 |

44.5 |

16 |

60 |

76 |

• |

• |

|

|

6.35 x 1.27 |

2.0 |

44.5 |

16 |

64 |

77 |

• |

• |

|

|

6.40 x 1.40 |

2.7 |

55 |

20 |

64 |

76 |

• |

• |

|

|

7.26 x 1.27 |

1.6 |

44.5 |

16 |

73 |

80 |

• |

• |

• |

|

7.26 x 1.60 |

2.5 |

66.7 |

19 |

73 |

75 |

• |

• |

|

|

9.60 x 2.08 |

3.5 |

97.8 |

25 |

96 |

75 |

• |

• |

|

|

12.0 x 1.83 |

2.3 |

80.0 |

29 |

120 |

81 |

• |

||

|

12.7 x 1.83 |

2.2 |

80.0 |

29 |

127 |

82 |

• |

• |

|

|

12.7 x 2.35 |

3.6 |

133.4 |

38 |

127 |

78 |

• |

• |

|

|

12.7 x 2.8 |

5.1 |

191.3 |

38 |

127 |

72 |

• |

• |

|

|

20.32 x 2.35 |

2.6 |

133.4 |

38 |

203 |

85 |

• |

||

Wire Belt Company produces in excess of 100 pitch & wire diameter specifications. If you do not locate your specification in the table above then please consult with Customer Services.

Available in widths ranging from 28mm to 4,500mm

*Check with our Technical Sales Engineers if the belt requires a smaller reverse bend diameter.

Materials available;

Flat-Flex® belts are available in a wide variety of materials; the standard is 1.4310 (302) stainless steel. Other materials available include: 1.4404 (316L) stainless steel, various carbon steels, and specialist materials suitable for high temperature applications.

Flat-Flex® can be supplied with a PTFE-coating for applications requiring a non-stick surface. High friction finishes are also available.

Edge loop types:

|

|

|

|

C-Cure-Edge™ |

Double Loop Edge (DLE) |

Single Loop Edge (SLE) |

|

Check the reference chart above for edge availability per mesh C-CureEdge™ Single Loop Edge technology eliminates the possibility of the belt edge catching and tangling. They are an available option for a selected range of Flat-Flex® belts. See above for availability listing. Click here to view further details. Double Loop Edges (also referred to as “Gear Wheel Edge”) can also be supplied to suit existing enrober belts. Single Loop Edges are the most common belt edge finish and are a default standard for 1.27mm wire diameters and above. |

||

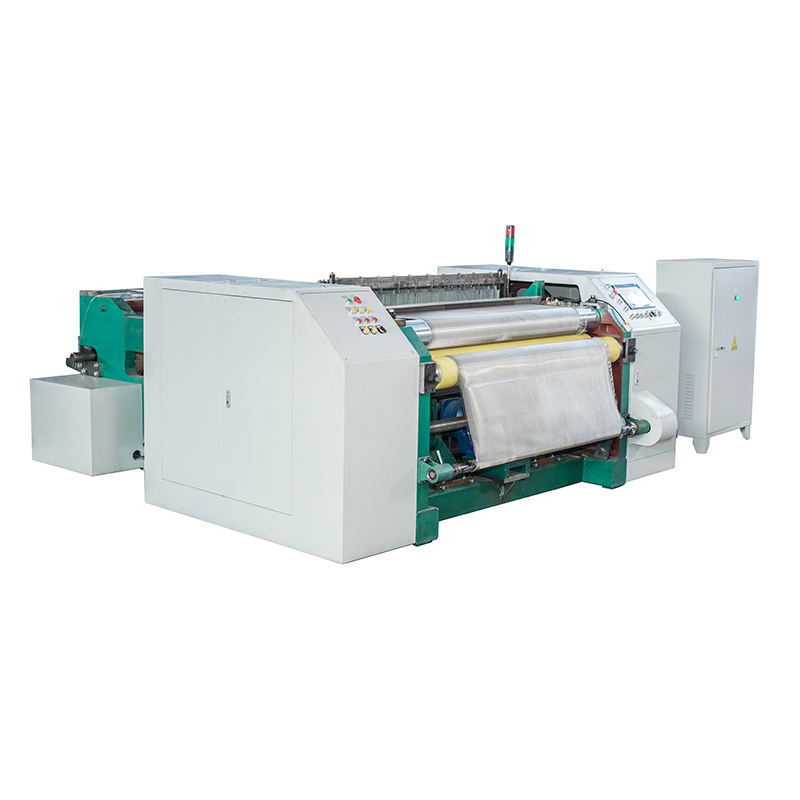

Flat-Flex® Drive Components

Sprockets and Blanks

When choosing the most appropriate sprocket material for your application, it is important to look at the conditions under which the belt will operate. Conditions such as abrasion, corrosion, high/low temperature variations, surrounding temperature, type of process performed, etc. all have an impact on sprocket selection.

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for 100% Original Ss Wire Mesh Belt - Wire Mesh Conveyor Belt Flat-Flex Type – JIKE, The product will supply to all over the world, such as: Cyprus, Berlin, Swiss, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.