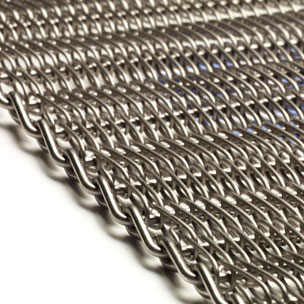

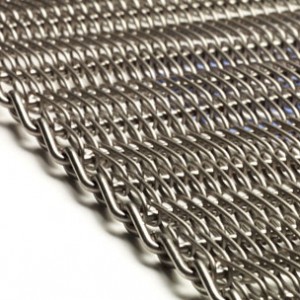

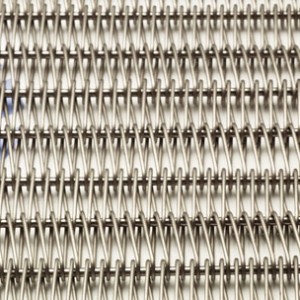

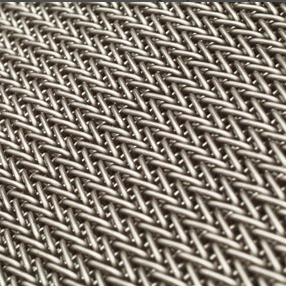

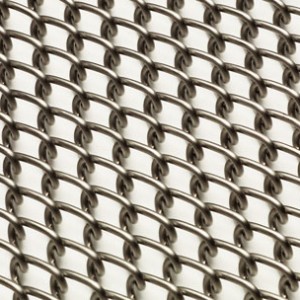

Flat Spiral is constructed from alternating left and right hand spiral coils, which are woven together and joined by interconnecting cross rods.

Flat Spiral’s alternating mesh design helps reduce tracking problems caused by the belt veering to one side. The small apertures present in the belt’s construction provides end-users with a flat conveying surface suitable for products prone to slipping through more open mesh designs.

The belt can be supplied with a welded, laddered or hook edge and is used in a friction driven conveyor layouts. Flat Spiralcan also be supplied with chain edges when a positive drive configuration is required. Flat Spiral is most commonly supplied in Grade 304 Stainless Steel, however, other materials are available on request.

Edge Availability

Laddered Edge (LD) – mesh only

Laddered cross wire is the standard edge finish for Flat Spiral belts. The belt edge is smooth and allows more belt edge flexibility. It is often used where welds are not desirable for the application. It is also more efficient in high temperature applications as the laddered edge is not under operational strain in use and therefore less prone to fracture.

Hook Edge (H) – mesh only

Less common than the laddered edge type the hook edge is also often used where welds are not desirable for the application. It is also an option in applications where welding facilities are not available. The belt edge is smooth and allows belt edge flexibility.

Welded Edge (W) – mesh only

This arrangement is less common than either the ladder or hook edge as there is reduced flexibility between the coil and cross wire at the edges. With the welding together of both the coil and cross wires there are no cut wire ends.

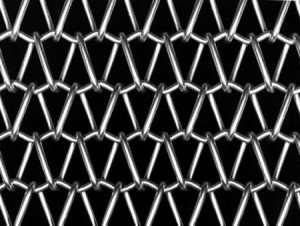

Chain Edge Driven Mesh

Along with the above mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then though chains at the edges of the mesh. The types of cross rod finish at the exterior of the side chain are as follows:

With welded washer

This is the most common and economical style of finish to a chain edge belt and comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. Depending upon the mesh cross wire pitch the cross rods may take the place of the through cross wire of the basic mesh. The cross rods are finished at the outside chain edges with a welded washer.

With cotter pin & washer

Although less economical this type of assembly allows the customer or service personnel the ability to replace the edge drive chains when the mesh and rods are still serviceable. The assembly comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. The cross rods are finished at the outside with a drilled hole to allow the fitment of a washer & cotter pin. It also allows the repair replacement of sections of belt without the need to grind off rod heads and weld back together.

NB: For greater width stability of rods to chain it is the norm, where possible, to supply the cross rods turned down to go through the edge chains.

Various other styles of chain edge finish

These include:-

a.Cross rod welded flush to the hollow pin of the side chain. This is not a preferred standard but may be necessary where width between conveyor side frames & other structural parts create a limitation where “welded washer” or “washer & cotter pin” cannot be used.

b.Cross rod welded flush through drilled hole on inner plates of roller conveyor chain.

In general the chain edge driven belts are available with 2 styles of edge chain:-

Transmission Chain - has a small roller

The chain edge side plate can be supported either on an angle side frame, or by means of a profiled rail to go between the side plates and support on the roller. Alternatively it can run without chain support where the mesh is supported close to the chain edge.

Conveyor Roller Chain –has a large roller.

This chain edge can be supported on a flat angle edge wear strip with the chain roller rotating freely along the conveyor length. The roller action of the chain reduces chain wear and also reduces the operational friction at this point.

Methods of Drive

Friction Driven

The most common form of drive is the plain steel parallel driven roller system. This system depends on the frictional contact between the belt and roller to ensure drive of the belt.

Variations of this drive type include the lagging of the roller with such materials as rubber, friction brake lining (for high temperature), etc. The use of such friction lagging materials allow for the operational drive tension in the belt to be reduced, thus increasing the useful life of the belt.

Chain Edge Driven

With this assembly of belt the cross wire pitch of the belt mesh is manufactured to ensure that the chain edge is the driving medium with the belt mesh being pulled through the circuit by the chains.

Standard Material Availability (Mesh Only):

|

Material |

Maximum Wire Operating Temperature °C |

|

Carbon Steel (40/45) |

550 |

|

Galvanised Mild Steel |

400 |

|

Chrome Molybdenum (3% Chrome) |

700 |

|

304 Stainless Steel (1.4301) |

750 |

|

321 Stainless Steel (1.4541) |

750 |

|

316 Stainless Steel (1.4401) |

800 |

|

316L Stainless Steel (1.4404) |

800 |

|

314 Stainless Steel (1.4841) |

1120 (Avoid use at 800-900°C) |

|

37/18 Nickel Chrome (1.4864) |

1120 |

|

80/20 Nickel Chrome (2.4869) |

1150 |

|

Inconel 600 (2.4816) |

1150 |

|

Inconel 601 (2.4851) |

1150 |