Top Quality Mesh Corner Bead - Crimped Wire Screen Material Mn65 M72 – JIKE Detail:

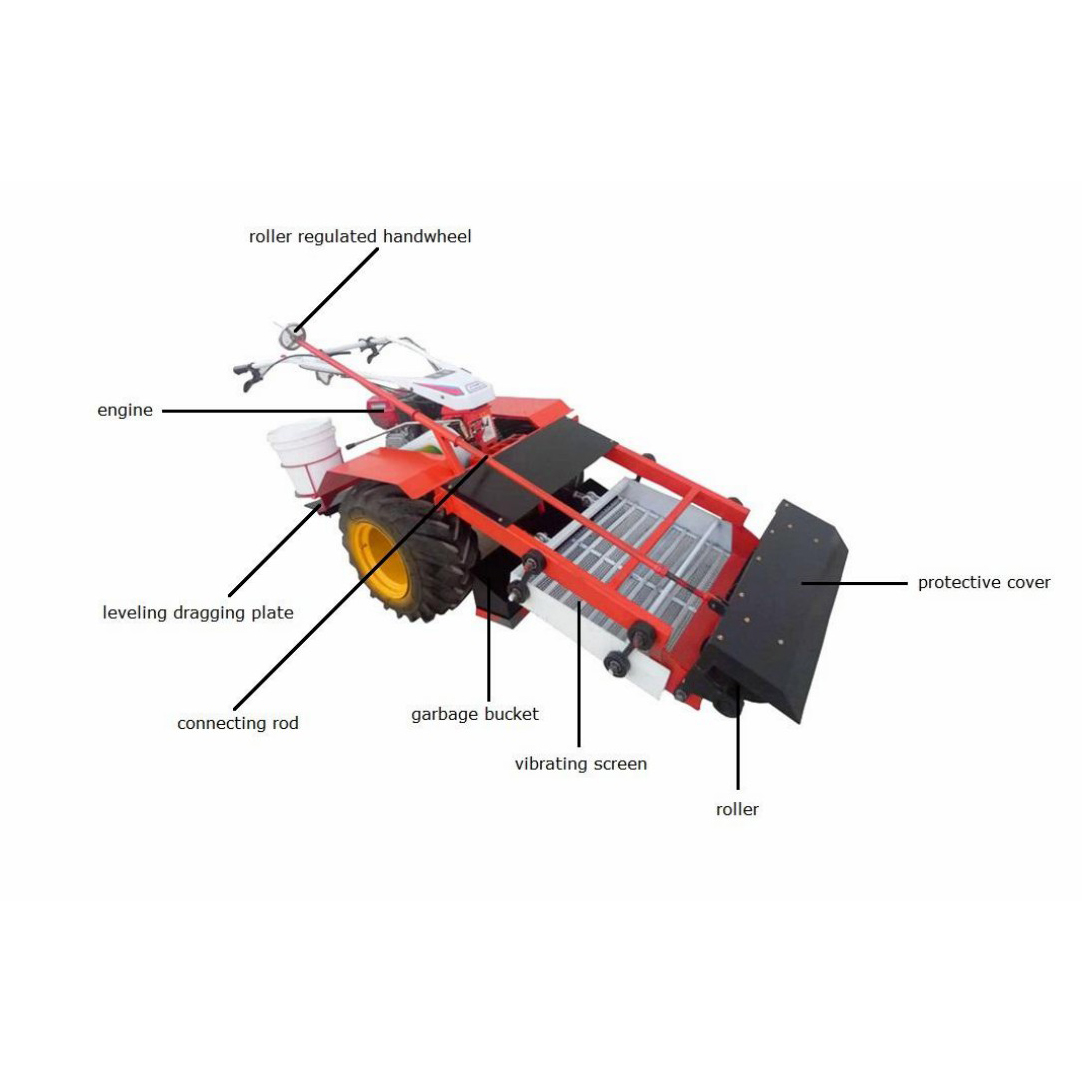

Crimped wire mesh is used in the waste water, oil refining, mining, construction, safety and food processing industries for applications that require strength and large-hole filtering and screening. Pre-crimped wire cloth is also used in architectural and industrial design applications.

heavy duty wire mesh is custom manufactured for products and applications requiring strength and rigidity, such as sieves and vibration filter media for sizing, sorting and filtering heavy or large materials. Heavy duty wire cloth is used in the mining, refining and construction industries.

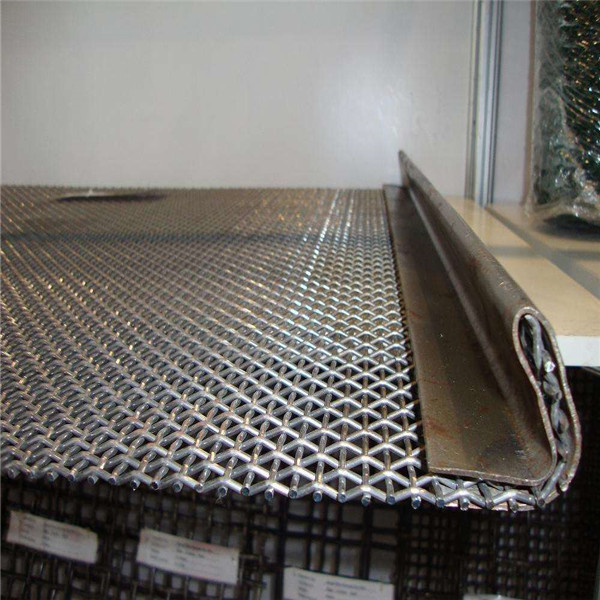

Pre-crimp wire cloth and heavy duty mesh are manufactured in large wire diameters. We offer a wide range of metals and alloys for use in the mesh to meet product requirements. AExtra-wide roll widths are available.

A full range of conversion services are available. These include slitting and shearing, electro polishing, forming and welding, and custom fabrications. If you have any questions about our pre-crimp and heavy duty wire products, please contact us today.

Conventional Double Crimp Woven Wire

Most common type of woven wire. It is used where the opening is relatively small in comparison to the wire diameter.

Lock Crimp Woven Wire

This woven wire type is used only in coarse specifications to maintain the accuracy of weave throughout screen life, where the opening is large with respect to wire diameter.

Inter Crimp Woven Wire

Used in coarse weaves of lighter gauge woven wire to provide greater stability, tightness of weave and maximum rigidity. Very common in wire mesh openings larger than 1/2″ (12.7mm).

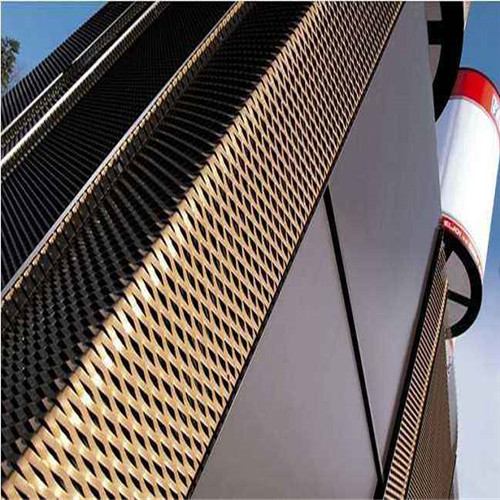

Flat Top Woven Wire

Usually starts at 5/8″ (15.875 mm) opening and larger. Provides long abrasive resistant life, since there are no projections on top to wear. Flat top woven wire offers the least resistance to flow and is very popular in certain architectural and structural applications where a smooth surface on one side is desirable.

|

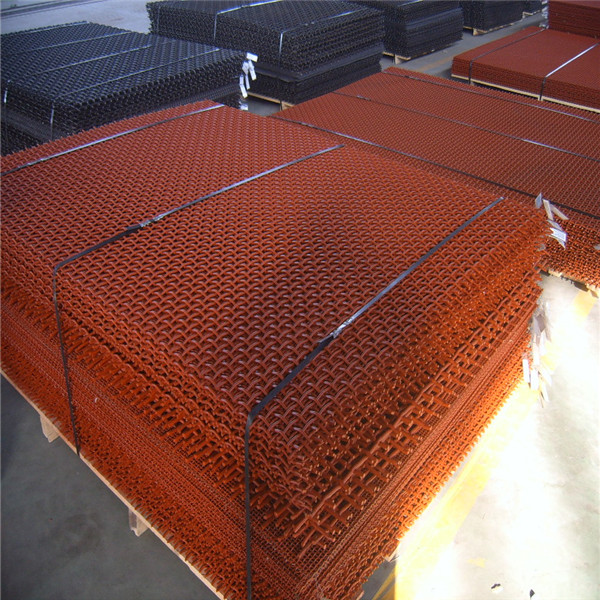

High tensile screen |

|||||||||

|

High tensile screen cloth commonly used in heavy duty applications for scalping and sizing of rocks,aggregates,limestone,etc |

|||||||||

|

High tensile steel—-Abrasion resistance |

|||||||||

|

Stainless Steel—-Corrosion Resistance |

|||||||||

|

Monel,Brass,etc—-General applications |

|||||||||

|

Specification for screen cloth |

|||||||||

|

Aperture |

Light Duty |

Medium Duty |

Heavy Duty |

||||||

|

square weave |

wire dia kg/m2 OA% |

wire dia kg/m2 OA% |

wire dia kg/m2 OA% |

||||||

|

2 |

2 |

11.3 |

31 |

||||||

|

3.15 |

2 |

9.9 |

37 |

2.5 |

14.1 |

31 |

|||

|

4 |

2 |

8.5 |

44 |

2.5 |

12.2 |

38 |

3.05 |

16.8 |

32 |

|

5 |

2 |

7.8 |

51 |

2.5 |

16.6 |

44 |

3.05 |

14.7 |

38 |

|

5.6 |

2.5 |

9.8 |

48 |

3.05 |

13.7 |

41 |

4 |

21.2 |

34 |

|

6.35 |

2.5 |

8.89 |

51 |

3.05 |

12.6 |

46 |

4 |

19.6 |

38 |

|

6.8 |

2.5 |

9 |

51 |

3.05 |

10 |

44 |

4 |

19.7 |

37 |

|

7.1 |

2.5 |

8.8 |

55 |

3.05 |

11.9 |

48 |

4 |

18.3 |

41 |

|

8 |

2.5 |

10.8 |

54 |

4 |

16.9 |

44 |

5 |

24.4 |

38 |

|

9 |

3.05 |

9.8 |

55 |

4 |

15.6 |

48 |

5 |

22.7 |

44 |

|

10 |

3.05 |

9.1 |

58 |

4 |

14.5 |

51 |

5 |

21.2 |

44 |

|

11.2 |

3.05 |

10.4 |

54 |

5 |

19.6 |

48 |

5.6 |

28.6 |

44 |

|

12.5 |

4 |

12.3 |

57 |

5 |

18.1 |

51 |

5.6 |

20 |

47 |

|

14 |

4 |

16.7 |

54 |

5 |

20 |

51 |

6.8 |

24.6 |

48 |

|

16 |

5 |

15.1 |

58 |

5.6 |

19.5 |

56 |

6.8 |

22.6 |

51 |

|

18 |

5 |

14.5 |

58 |

6.8 |

20.7 |

55 |

7.1 |

25 |

51 |

|

20 |

5.6 |

14 |

61 |

6.8 |

19.2 |

58 |

7.1 |

24 |

54 |

|

22 |

5.6 |

17.6 |

61 |

7.1 |

21.5 |

57 |

8 |

26.7 |

54 |

|

25 |

6.8 |

16.1 |

64 |

7.1 |

20.1 |

60 |

8 |

24.6 |

57 |

|

28 |

7 |

14.7 |

63 |

8 |

19 |

61 |

9 |

27.8 |

57 |

|

32 |

8 |

20.6 |

64 |

9 |

26 |

60 |

10 |

30.4 |

58 |

|

38 |

8 |

18.7 |

67 |

9 |

28.1 |

64 |

10 |

27.9 |

61 |

|

40 |

9 |

21 |

67 |

10 |

25.4 |

64 |

11.2 |

31.1 |

61 |

|

45 |

9 |

19.5 |

69 |

10 |

23.4 |

67 |

11.2 |

28.4 |

64 |

|

50 |

10 |

23.2 |

69 |

11.2 |

26 |

67 |

12.5 |

31.8 |

64 |

|

56 |

10 |

19.2 |

72 |

11.2 |

28.7 |

69 |

12.5 |

29 |

67 |

|

63 |

10 |

17.4 |

75 |

11.2 |

24.5 |

72 |

12.5 |

25.1 |

70 |

|

76.2 |

10 |

14.8 |

78 |

11.2 |

16 |

75 |

12.5 |

20 |

73 |

|

80 |

10 |

16 |

79 |

11.2 |

17.5 |

72 |

12.5 |

21.5 |

75 |

|

90 |

10 |

14 |

81 |

11.2 |

15.7 |

79 |

12.7 |

19.4 |

77 |

|

100 |

10 |

10 |

82 |

11.2 |

14.3 |

81 |

12.7 |

17.6 |

79 |

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Top Quality Mesh Corner Bead - Crimped Wire Screen Material Mn65 M72 – JIKE, The product will supply to all over the world, such as: Rwanda, Bulgaria, South Africa, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.