-

Fe-Cr-Al sintered fiber felt

Fe-Cr-Al fiber sintered felt is a metal fiber sintered felt with long service life, environmental protection and energy saving, high temperature resistance, deformation resistance, no carbon deposition, good toughness, foldability, and uniform pore size distribution. It has very high porosity and dirt holding capacity, and is widely used in parking heaters, boiler transformation, coking plants, gas air conditioners, glass annealing, food baking, ovens, heaters, carbon-coated paper, drying, dust removal and other fields.

-

Polyester Monofilament Screen Printing Bolting Silk Screen Textile 12-460 mesh 100%

Nylon screen printing mesh, also called PA screen printing mesh, is made of polyamide yarn. It is an alternative to polyester screen printing mesh for various substrates printing, especially in ceramic, plastic and glass industries.

Nylon screen printing mesh has excellent abrasive resistance performance to be used with high abrasive inks and the high elasticity performance make it easy to printing hollow ware glass or ceramics.

-

Different Size Laboratory Woven Wire Mesh Stainless Steel Test Sieve

test sieve is individually manufactured under the most stringent quality control procedures using only the finest materials. We use the most advanced computer scanning techniques to ensure precise test sieve apertures. Our skill and experience ensures you will not only receive a test sieve that looks and feels good, but one that offers a degree of accuracy second to none.

-

Stainless Steel Wedge Wire Johnson Screen for Water Well Drilling

Wedge wire screen is a metal mesh element widely used in screening, filtration, dehydration and desliming operations for sieving and filtration. It has high strength, rigidity and load carrying capacity and can be made into a variety shapes of rigid screening filters.

The wedge wire screen consists of surface profiles and support profiles. Surface profiles, usually v-shaped wires, are wrapped and welded onto support profiles. The distance between the surface profiles is controlled very accurately, as it forms the slot through which the filtrate flows. The direction of the flow is determined by the position of V-shaped wires (surface profiles) in relation to the support profiles. Wedge wires screens are either flow-out-to-in or flow-in-to-out.

-

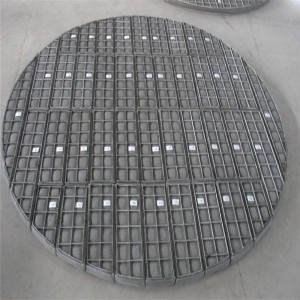

Wire Mesh Demister Pad for Tower Internals for Gas-Liquid Seperation

Demister pad also called mist pad, wire mesh demister, mesh mist eliminator, catching mist, mist eliminator, is used in gas entrained mist separation column to guarantee the filtering efficiency.

-

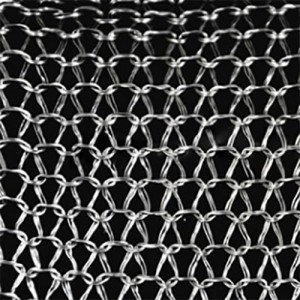

Stainless Steel Knitted Wire Mesh Tube

Knitting wire mesh tube, can be one single layer or multi-layer, Solid or hollow as request.

Also called knitted shielding sealing rope, electromagnetic shielding mesh -

Stainless Steel Knitted Wire Mesh filter

Knitted wire mesh rolls refer to the various materials are knitted into knitted wire mesh and then the wire meshes are rolled up for convenient usage and transport.

Knitted wire mesh rolls are available for various materials, the common materials are stainless steel wire, galvanized wire, copper wire, brass wire, nickel wire and monel wire.

-

Wire Mesh Filter Disc For Plastic Extruder

It has better performance in damper environment or where paper filter discs couldn’t supply sufficient rigidity and strength. It also features outstanding durability and suitable ability. Therefore it not only can withstand temperature range in excess of 500 F and high pressure but also can be manufactured by spot welding and perforating. What’s more, filter discs can be designed to be compatible with most caustic fluids and they are cleanable and reusable. Therefore, compared with paper and cloth filter discs, metal filter discs can offer a long service life.

-

Stainless Steel Sintered Wire Mesh Filter Elements

Sintered wire mesh metal filter cloth is a porous metal plate made from multilayer stainless steel wire mesh, and sintered into one metal panel. It is usually consists of 5 layer (or 6-8 layer) mesh: protect mesh layer, filter mesh layer, protection mesh layer, reinforcement mesh layer, and reinforcement mesh layer. With high mechanical strength and wide filter rating ranges, sintered filters are a new fine materials for filtration used in food, beverage, water treatment, dust removing, pharmaceutical, and polymer industry.

The materials of sintered wire mesh commonly is stainless steel 304, SS316,SS316L, but Alloy Steel Hastelloy, Monel, Inconel and other metal or alloy as materials also available according customers filter process requirement. Sintered stainless steel filter is the most widely used type among all the materials due to its excellent chemical stability and long service life.

The protect mesh layer and filter layer are fine stainless steel woven wire mesh, and reinforcement mesh layer can be plain woven, dutch woven type wire or perforated metal sheet.

Sintered mesh filter cartridges from stainless steel wire cloth with filter rating 1-250 micron for pharmaceuticals, fluidized beds, liquid and gas filtration.

-

Stainless Steel Sintered Wire Mesh for Making Filter

Sintered wire mesh metal filter cloth or panel is a porous metal plate made from multilayer stainless steel wire mesh, and sintered into one metal panel. It is usually consists of 5 layer (or 6-8 layer) mesh: protect mesh layer, filter mesh layer, protection mesh layer, reinforcement mesh layer, and reinforcement mesh layer. With high mechanical strength and wide filter rating ranges, sintered filters are a new fine materials for filtration used in food, beverage, water treatment, dust removing, pharmaceutical, and polymer industry.

The materials of sintered wire mesh commonly is stainless steel 304, SS316,SS316L, but Alloy Steel Hastelloy, Monel, Inconel and other metal or alloy as materials also available according customers filter process requirement. Sintered stainless steel filter is the most widely used type among all the materials due to its excellent chemical stability and long service life.

The protect mesh layer and filter layer are fine stainless steel woven wire mesh, and reinforcement mesh layer can be plain woven, dutch woven type wire or perforated metal sheet.

-

Stainless Steel Hastelloy FeCrAl Nickel Sintered Metal Fiber Felt

It is a non-woven media-constructed through the randomly laying short metal fibers then subjected to sintering and bonding . Sintered metal fiber felt is best suited for use in applications that operate under very high pressure,high temperature,and corrosive environments. The fleece of the metal fiber can comprise different layers of fiber. They can be compressed together to a suitable thickness then sintered to fuse the respective single fibers. The resulting material is a highly porous fiber that is very strong,resistant to corrosion,high temperature,and fracture. Furthermore,it has excellent permeability and can last longer compared to common media.

-

Various Mesh Size Stainless Steel Woven Wire Mesh in Stock

We offer a full line of woven wire cloth and woven mesh products to meet the requirements for a wide range of applications. We manufacture and supply custom wire cloth of all varieties including plain, twilled, dutch, and reverse dutch and twill. we designs woven wire cloth to meet specific product requirements, reducing clients’ costs and increasing production efficiency. Our affiliate weaving and mills manufacture wire cloth and mesh to meet clients’ internal specifications, ISO, ASTM and DIN standards.